Prop Pillow: Smart Comfort System

Role: Hardware Engineer & Circuit Designer | Collaborative Project with 4 Classmates | Duration: Dec 2021 - Jun 2022

Prop Pillow is an innovative smart pillow system that provides dynamic comfort through real-time adjustable firmness. Building on experience from previous projects involving solenoids and smart control systems, our team developed a compact, battery-powered solution that seamlessly combines hardware and software for optimal user comfort.

Prop Pillow Demonstration: Real-time Firmness Adjustment

Adaptive Support

Real-time inflation and deflation for customizable comfort

Quiet Operation

Low noise air pump with vibration dampening

Long Battery Life

8-10 hours of intermittent use on a single charge

Wireless Control

RF remote for easy firmness adjustment

Development Process

Research & Ideation

December 2021 - January 2022

- Finalized core concept

- Conducted preliminary tests

- Selected key components

Initial Prototyping

February 2022

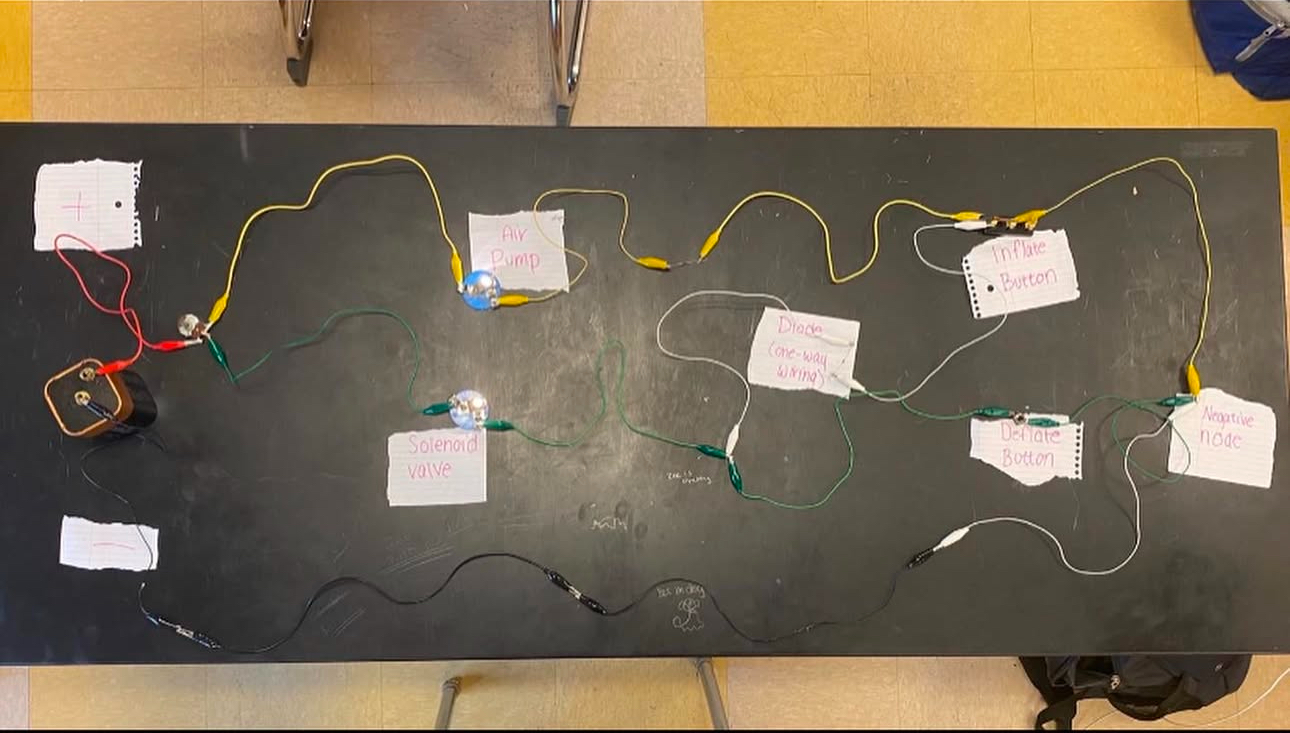

- Created first breadboard circuit

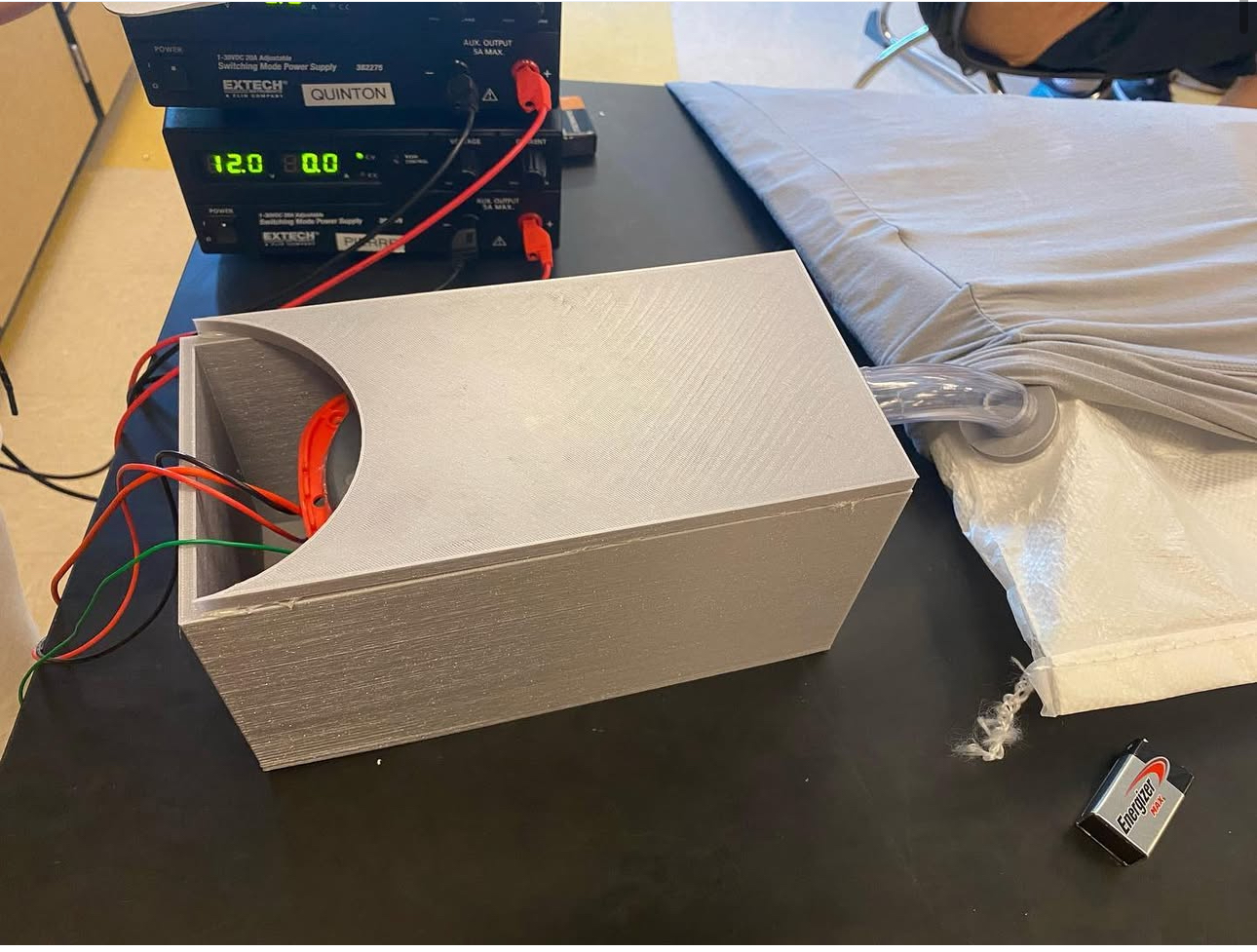

- Developed 3D-printed casing

- Tested component integration

Iteration & Testing

March - April 2022

- Added RF remote control

- Improved noise reduction

- Conducted user trials

Final Refinements

May - June 2022

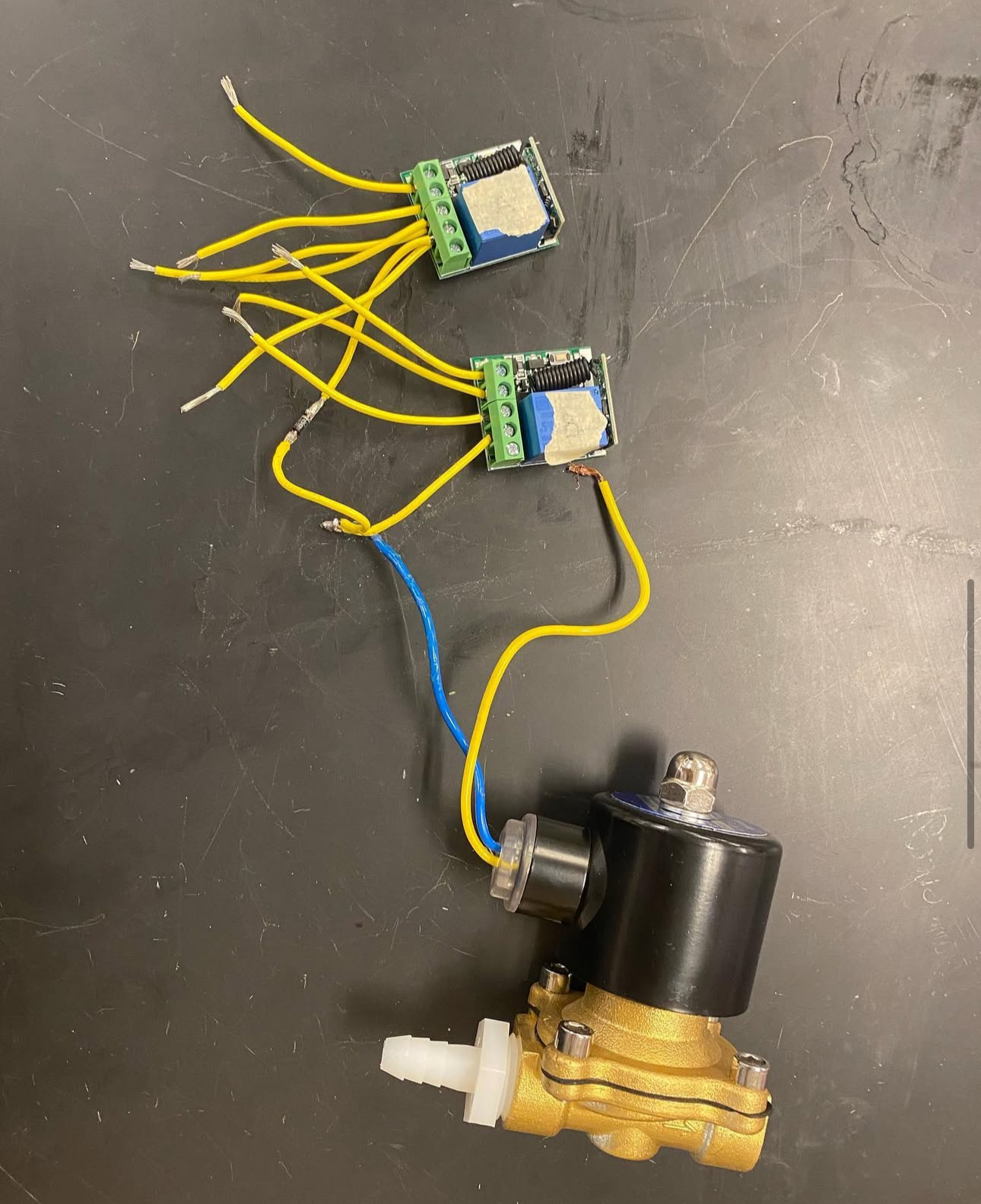

- Enhanced solenoid design

- Optimized battery life

- Finalized production design

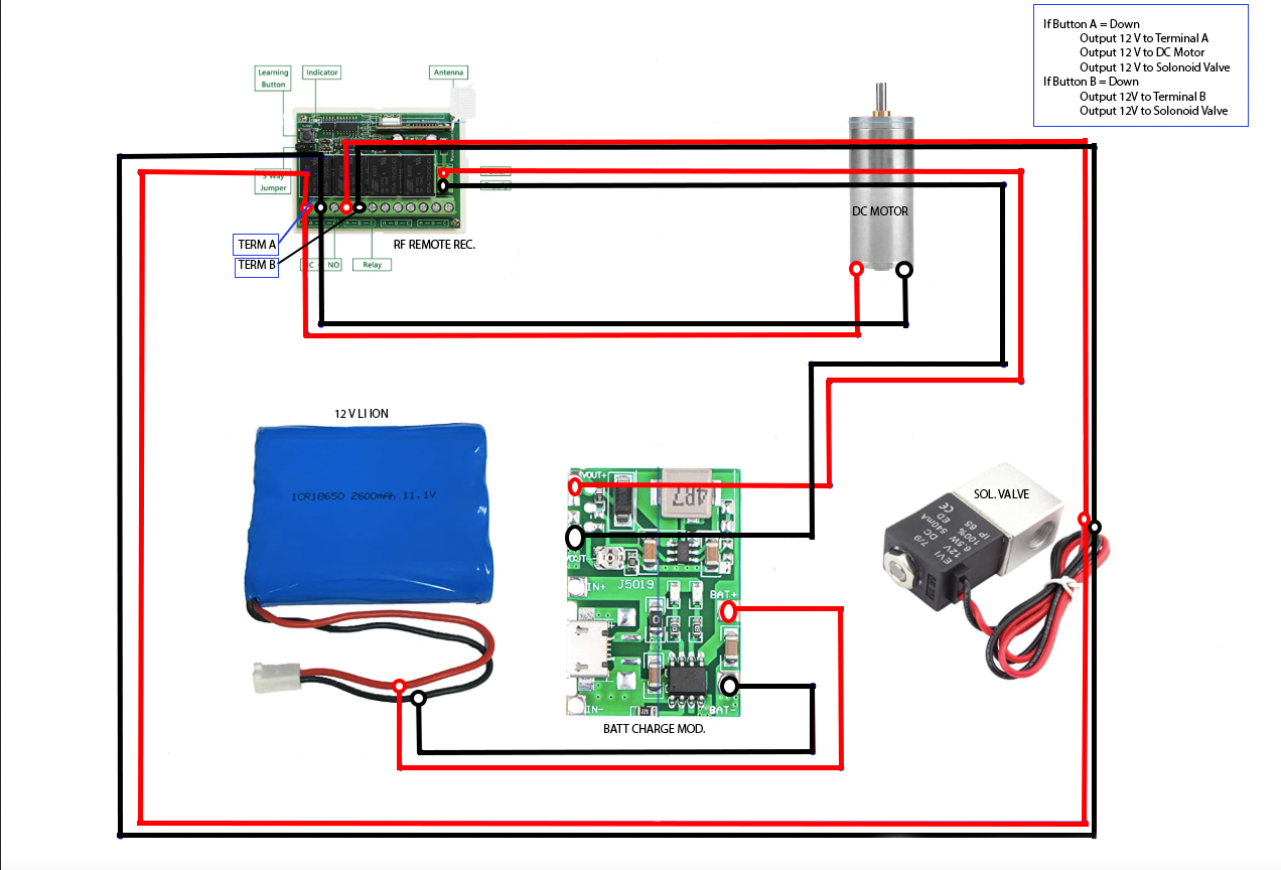

Technical Implementation

Power System

- 12V Li-ion Battery Pack (3S)

- 8-10 Hour Battery Life

- Integrated Charging Circuit

Control System

- 433MHz RF Remote Control

- Arduino-based Logic

- PWM Motor Control

Air System

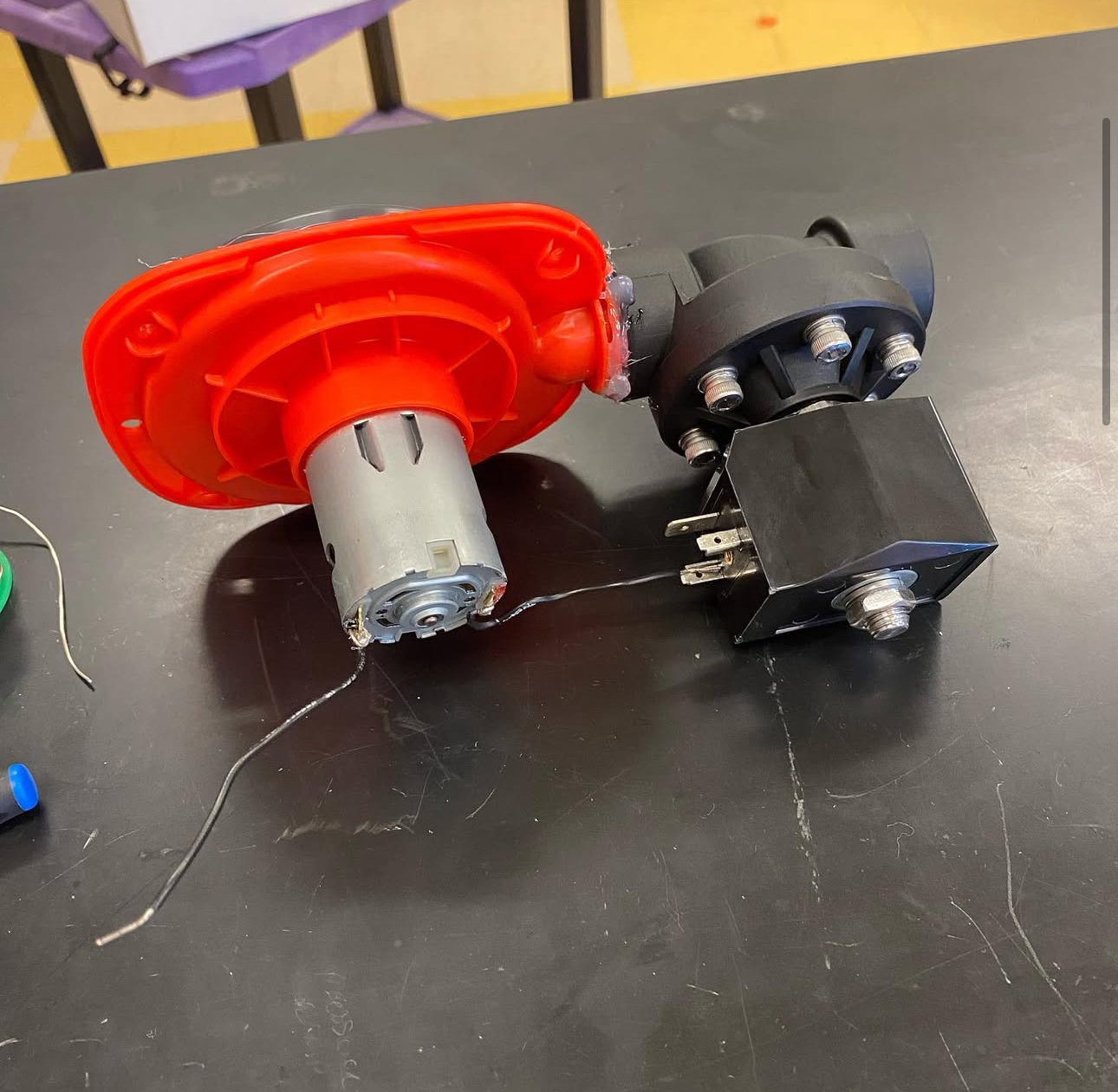

- 12V DC Air Pump

- Normally Closed Solenoid

- Check Valve Protection

Prototyping & Iterations

Mechanical Design

- 3D-printed housing (12cm × 8cm × 6cm)

- Rubber dampeners for noise reduction

- TPU/PVC air bladder design

Noise Reduction

- 15-20 dB noise reduction

- Sound-dampening foam

- Vibration isolation mounts

User Interface

- Intuitive RF remote

- LED status indicators

- Backup manual controls

Team Structure & Roles

Developed as part of a five-person team at Indiana University, this project exemplifies collaborative engineering at its best. Our diverse team brought together complementary skills in hardware, software, and mechanical engineering, with each member taking ownership of critical aspects of the project.

Lead Hardware Engineer

My Role: Circuit Design & Integration

- Power management system design

- RF communication integration

- Battery performance optimization

Software Lead

Control Systems & Programming

- Core control algorithms

- RF protocol development

- System integration

Mechanical Design

Physical Implementation

- 3D modeling & printing

- Acoustic optimization

- Assembly design

Project Coordination

Management & Planning

- Sprint planning

- Resource management

- Documentation

Quality Assurance

Testing & Validation

- Test protocol design

- User experience research

- Performance validation

Each team member brought unique perspectives and skills to the project, fostering an environment of collaborative innovation. Regular team meetings and agile development practices ensured effective communication and rapid iteration on design improvements.

Project Gallery

Technical Documentation

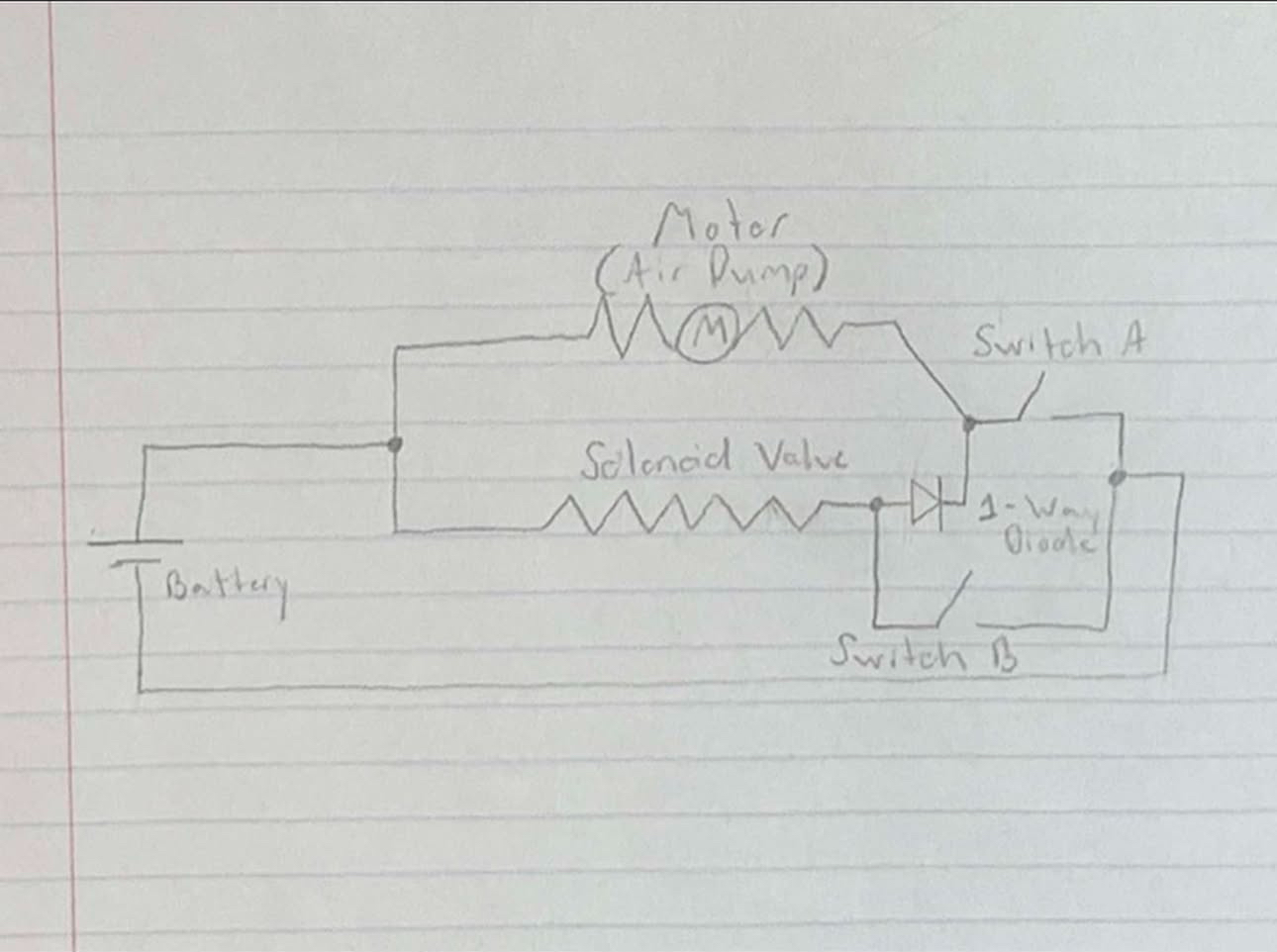

Detailed Circuit Diagram and Component Layout

Downloads & Resources

3D Models

- Main Housing (Part Studio 2)

- Pump Mount (Part Studio 3)

- Fan Blade (Bd920FanBlade)

Documentation

- Circuit Schematics

- Assembly Guide

- User Manual