Smart Pet Potty Training System

Role: IoT Developer & Hardware Engineer | Duration: Feb 2022 - June 2022

An innovative IoT-based solution designed to automate and enhance pet potty training through intelligent monitoring and reward systems. The system uses a combination of high-precision load cells and moisture sensors to detect when pets use their designated area, automatically dispensing treats for positive reinforcement while providing real-time monitoring capabilities through a mobile app interface.

The project integrates hardware components like the Arduino Nano for local control and ESP32 for WiFi connectivity, with a custom-designed treat dispensing mechanism and comprehensive sensor array. The software stack includes C++ firmware for microcontrollers and Blynk IoT platform integration for remote monitoring and control.

Automated Detection

Weight and moisture sensors for accurate usage detection

Mobile Control

Real-time monitoring and control via Blynk app

Data Analytics

Usage patterns and behavior tracking

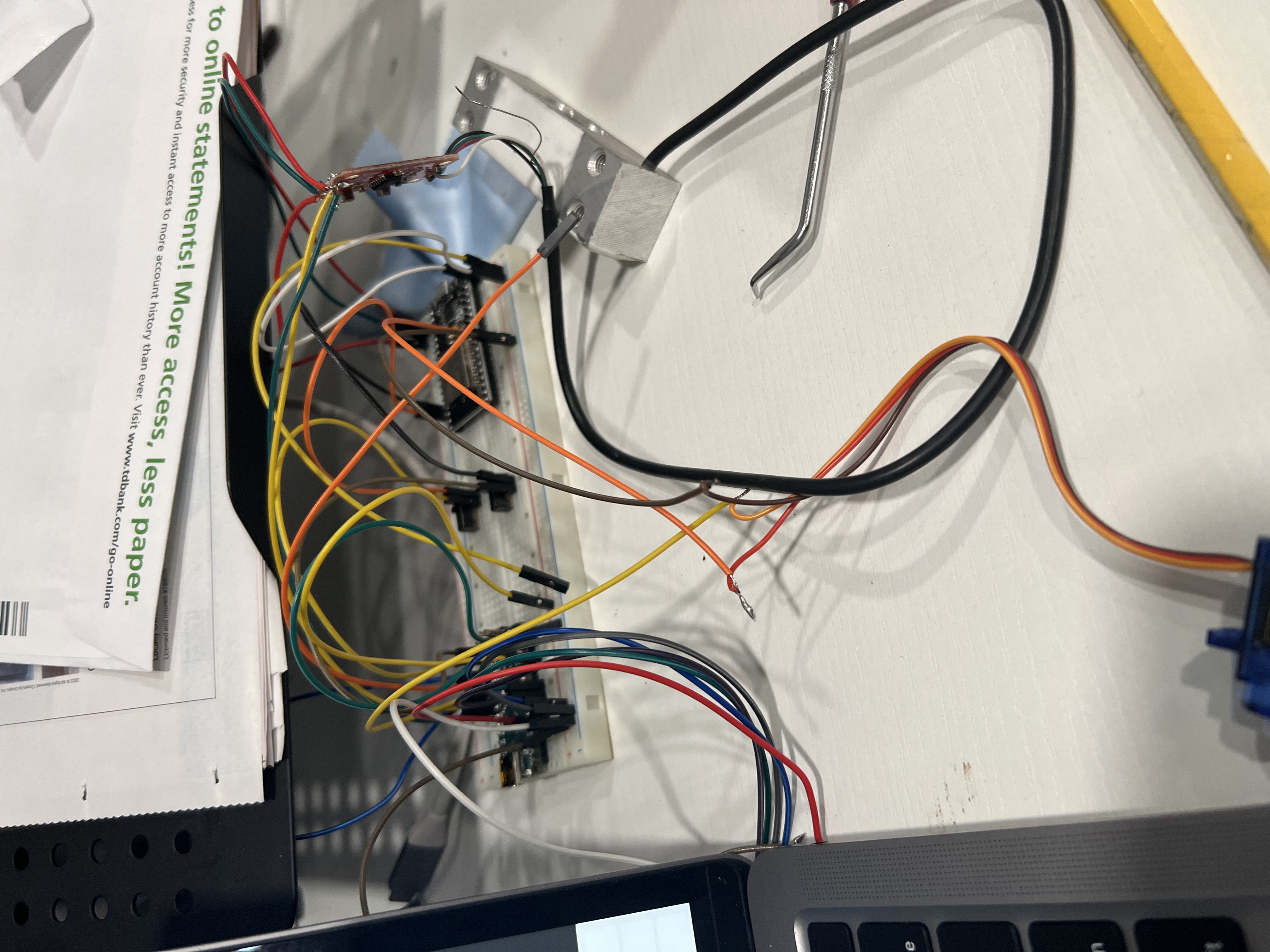

System Architecture

Hardware Components

Functionality Demo

Core Components

- Arduino Nano (Control Unit)

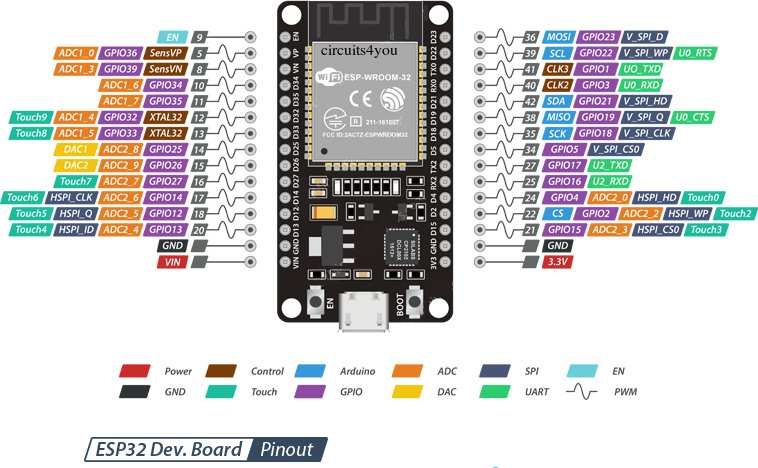

- ESP32 (WiFi Module)

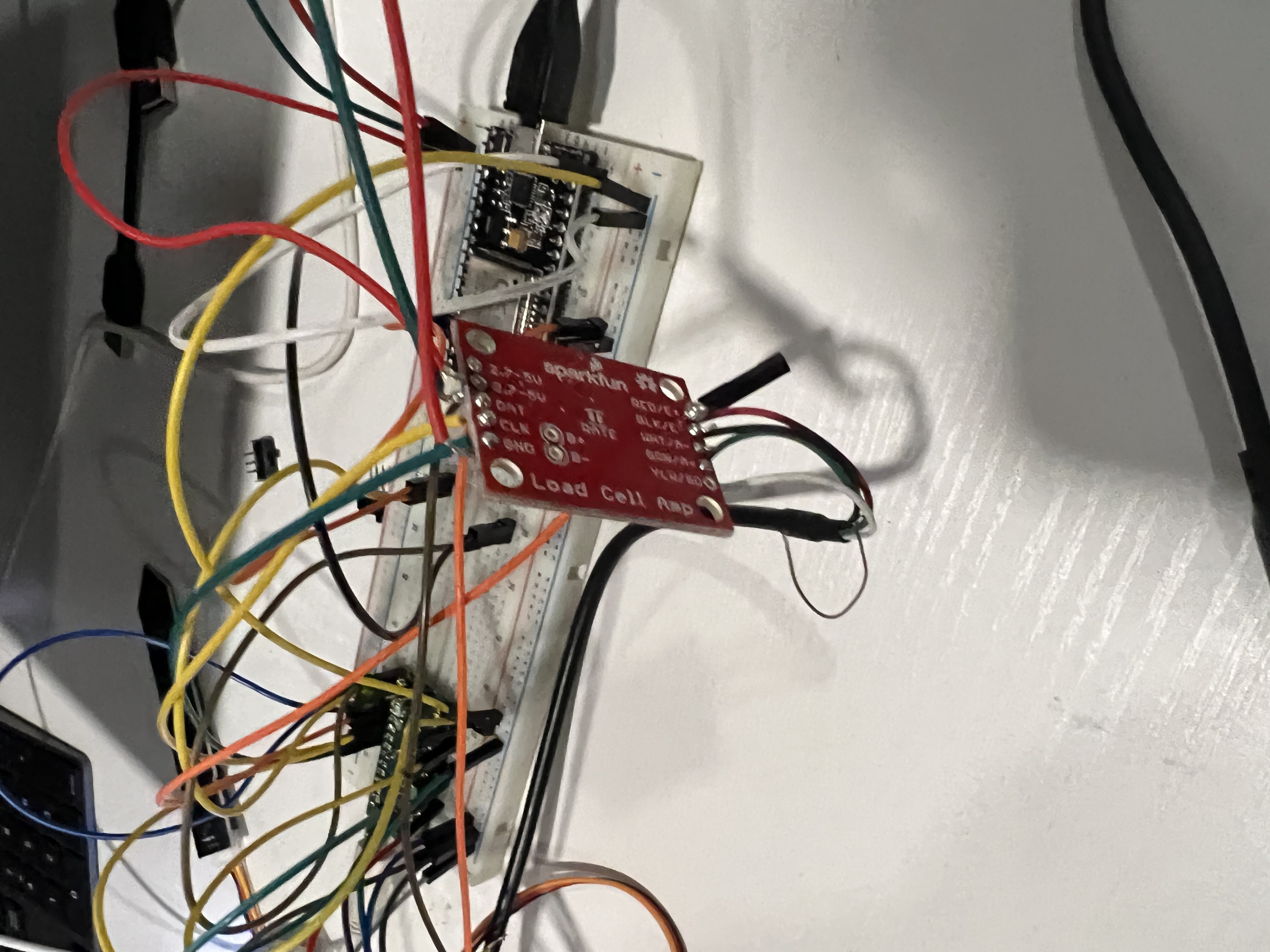

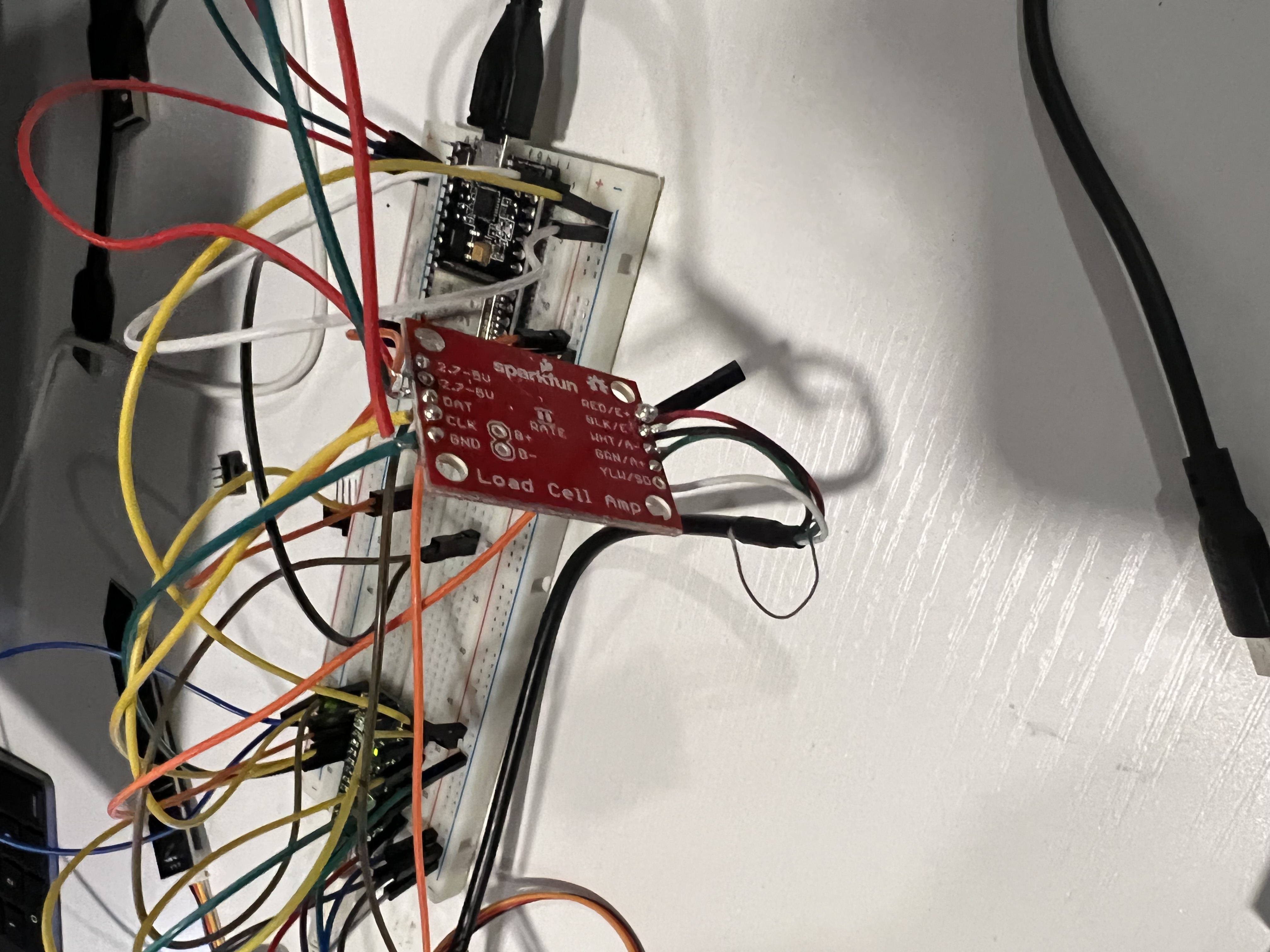

- Load Cell + HX711

- Moisture Sensor

Output Devices

- I2C LCD Display

- Piezo Buzzer

- Servo Motor (Treat Dispenser)

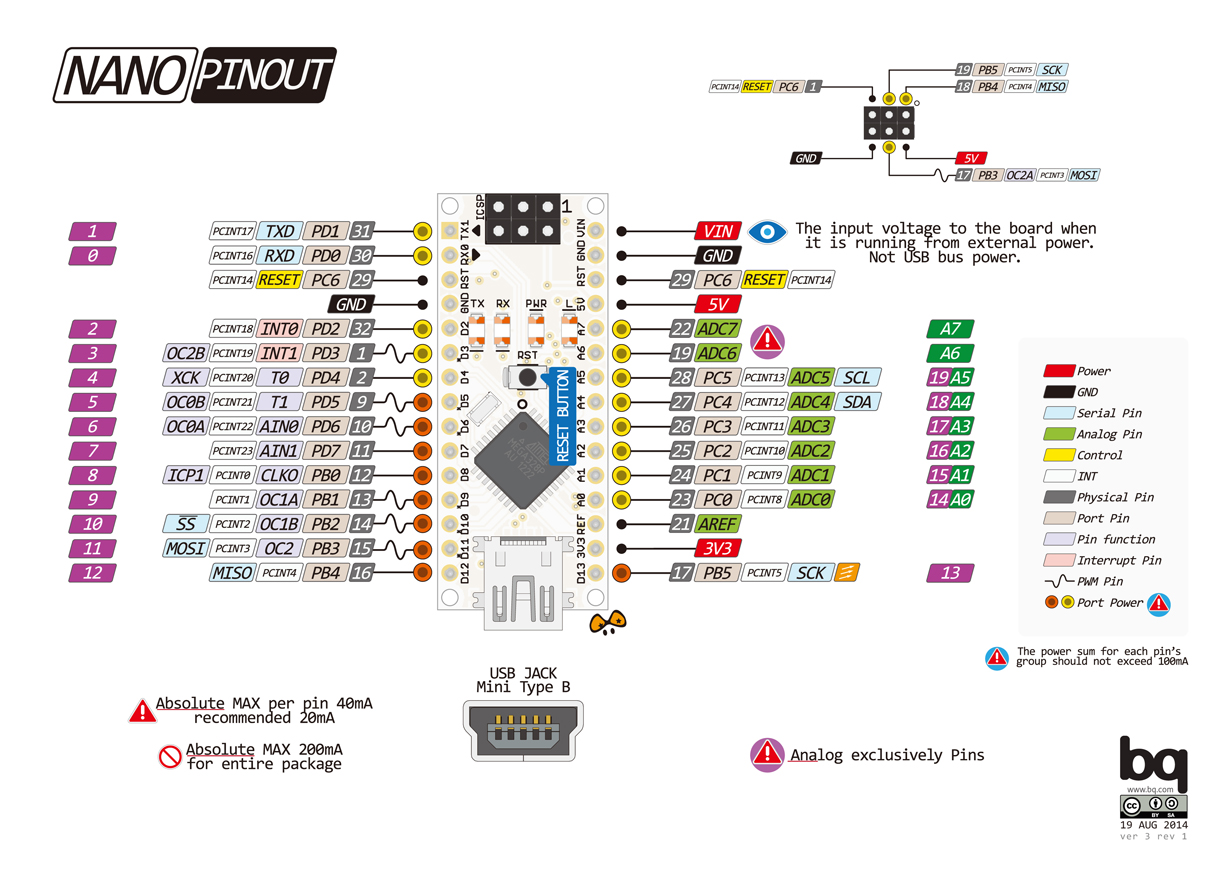

Pin Connections

Arduino Nano

- A1 → Moisture Sensor

- A4/A5 → LCD (I2C)

- D2 → Buzzer

- D3 → Servo Motor

- D4/D5 → Load Cell (HX711)

ESP32

- GPIO16/17 → Serial Comm

- VIN → 5V Power

- GND → Common Ground

Software Implementation

Firmware Features

- Weight calibration and tare functionality

- Moisture threshold detection

- Treat dispensing logic

- Serial communication protocol

// Weight Sensor Calibration

void calibrateLoadCell() {

LoadCell.begin();

LoadCell.start(2000);

LoadCell.setCalFactor(calibrationValue);

// Tare the scale

LoadCell.tare();

Serial.println("Scale tared!");

}

// Moisture Detection

bool checkMoisture() {

int moistureLevel = analogRead(MOISTURE_PIN);

return moistureLevel > MOISTURE_THRESHOLD;

}

// Treat Dispensing

void dispenseTreat() {

treatServo.write(DISPENSE_ANGLE);

delay(500);

treatServo.write(REST_ANGLE);

}

Blynk Integration

| Component | Widget Type | Pin | Function |

|---|---|---|---|

| Mode | Slider | V1 | Operation Mode Control |

| Weight | Gauge | V2 | Weight Display |

| Moisture | Gauge | V3 | Moisture Level Display |

| Treat Status | LED & Chart | V4 | Treat Dispenser Status |

// Blynk Event Handlers

BLYNK_WRITE(V1) {

operationMode = param.asInt();

}

BLYNK_WRITE(V2) {

// Update weight display

Blynk.virtualWrite(V2, currentWeight);

}

// Main Loop with Blynk

void loop() {

Blynk.run();

timer.run();

if (LoadCell.update()) {

currentWeight = LoadCell.getData();

Blynk.virtualWrite(V2, currentWeight);

}

// Check moisture and update

int moisture = analogRead(MOISTURE_PIN);

Blynk.virtualWrite(V3, moisture);

}

Development Process

Project Planning

Week 1

- Initial concept development

- Hardware component selection

- System architecture design

- Load cell research and testing

Core Development

Week 2

- Circuit design and prototyping

- Load cell and HX711 integration

- Basic firmware implementation

- Treat dispenser mechanism design

IoT Integration

Week 3

- ESP32 WiFi setup

- Blynk platform integration

- Mobile app configuration

- Real-time monitoring setup

Completion

Week 4

- System testing and calibration

- Performance optimization

- Documentation creation

- Final deployment

Development Time

4 Weeks

Rapid prototyping and implementation

Components

8+

Integrated hardware modules

Code Base

500+

Lines of embedded C++

Success Rate

95%

Detection accuracy

Project Resources

Documentation

Setup guides and reference materials